tekflo sensors are proud to present their tekSon TS Series ultrasonic water energy meter, which uniquely meets EN1434 Class 1 total energy system accuracy for pipe sizes 15mm to 2000mm (1/2” – 80”) pipe diameter.

tekSon measures hot or chilled water energy by continuous sensing of the multiplication of flow rate and the differential temperature of the inlet and outlet temperature to a chiller or heat generator.

The versatile TS ultrasonic flow sensors may be clamped horizontally on the same side of the pipe on existing hot or chilled water pipes from 15mm (1/2) diameter. Alternatively, they may be inserted diagonally opposite each other into weld bosses at an angle to the centre line on existing pipes from 32mm (11/4”). A complete spool piece is also available for pipe sizes from 25mm (1”). All types have a maximum diameter of 2000mm (80”).

Twin tekSon ultrasonic sensors operate on the most accurate time of flight principle, employing 4-byte IEEE 754 floating point computation. Each sensor embodies a solid state piezo-ceramic crystal, which acts alternatively as transmitting or receiving ultrasonic pulse generators, in either V formation up to 50mm or diagonally for the larger pipes. In each case the flow rate is proportional to the time difference between the transmitted and received ultrasonic pulses.

The complete system including flow sensing, matched differential temperature sensing and the all-digital computation of energy, meets EN1434 Class 1 system accuracy of < ± 1 of reading over a 10 : 1 energy flow range and < ± 1.2% of reading over a 30 : 1 energy flow range. Each tekSon flow sensor is supplied with a customised flow Calibration Certificate traceable to USA NIST (National Institute of Standards and Technology). The temperature sensors are certified to meet a minimum differential temperature of 3º Kelvin with EN1434 Class 1 accuracy status.

Features:

- The only ultrasonic energy system meeting EN1434 Class 1 for sizes from 15 – 2000mm diameter

- tekSon flow sensors are custom calibrated with system certified accuracy traceable to USA NIST

- Independent of media density changes caused by variation in additives, such as ethylene glycol, propylene glycol, brine etc. Note: turbine flow or other small meters cannot claim this.

- Low cost. Clamp-on sensors installed on existing pipe lines have no pipe modification costs

- Suitable for metal or plastic PVC/FRP and similar pipes

- Flow and temperature sensors are submersible to IP68 and NEMA 6 P to 1 m water gauge

- Clamp-on sensors may be used for NIST traceable on-site revalidation of other energy sensors

- Matched temperature sensors certified to a minimum differential of 3º Kelvin with NIST traceability

- 3-wire Pt 100 temperature sensors suitable for minus 30 to + 160º C (minus 22 to + 320º F)

- Solid state, non- media contact flow sensors with no moving parts

- Zero pressure loss, unlike turbine type meters or Spire’s labyrinth ‘Z’ ultrasonic system

- Suitable for small air bubble entrainment and turbidity to 10000 ppm

- Continuous mean velocity sensing from zero to 10 m/s. No mechanical cut-off.

- 4-20mA and scaled pulse, isolated hi/lo relay outputs, RS485 data interface

- 3 x 4-20mA inputs for use with alternative magnetic flow sensors, pressure, level and temperature

Why tekSon Zero Pressure Drop Is Important

A requirement of EN 1434 is that manufacturers must specify pressure drop across their flow sensor. Pressure drop can affect accuracy of an energy flow metering system since it increases the pump energy consumption. If the pump cannot compensate for the pressure drop, which increases with the square of the flow rate, the chilled or hot water flow may easily fall below design requirements. This in turn may cause a reduction in a building’s heating or cooling capacity and reduction in energy efficiency of the heating or cooling appliance, especially if it uses a heat pump.

tekSon plays an important role in alleviating the above problem caused by pressure drop. Consider competitive flow metering pressure drops at normal flow rates with tekSon:

| Company and Flow Sensor Type | Pressure Drop At Normal Flow Rate |

|---|---|

| Onicon Insertion Turbine | 0.1 bar (> 150mm pipe), 0.2 bar (< 150mm pipes) |

| Signet Paddle Wheel | 0.1 bar (> 150mm pipe), 0.2 bar (< 150mm pipes) |

| Sprire Labyrinth Z Ultrasonic | 0.15 – 0.2 bar small pipes onlyCompact or remote Battery powered < +- 1% of reading |

| Landis & Gyr Ultrasonic | 0.15 – 0.2 bar small pipes only |

| tekSon Ulrasonic | Zero at max flow 15 – 2000mm pipes |

About EN1434

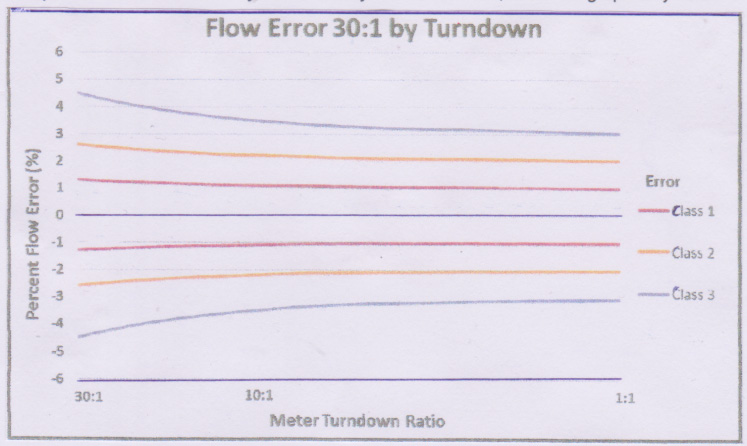

EN1434 is a European Standard specifying the combined accuracy of the flow sensor, the pair of temperature sensors and the electronics in which the calculation is performed, displayed and transmitted. Cooling water and hot water energy metering systems are classifies by the combined system accuracy in terms of Class 1, 2, or 3 as follows:

Ei = ± ( 1 + 0.01qp/q ) but not > 3.5%………Class 1

Where Ei = % uncertainty in energy measurement

qp = highest flow rate at which the flow sensor continuously function

q = actual operating flow rate

Note: Flow sensors with moving parts should guarantee the ‘continuous function life’

Similarly, Ei = ± ( 2 + 0.02qp/q ) but not > 5%………Class 2

and Ei = ± ( 3 + 0.05qp/q ) but not > 5%………Class 3

To this EN1434 specifies that the temperature error of the temperature sensor pair is arithmetically added to the combined errors above, not root of the sum of the squares):

Et = ± ( 0.5 + 3ΔǾmin/ΔǾ )

Where Et = % uncertainty in the differential temperature sensing

ΔǾmin = minimum temperature difference of temperature sensors

ΔǾ = actual operating temperature difference

tekSon temperature sensors are accurately matched to meet a minimum differential temperature of 3º Kelvin to provide a total arithmetic system accuracy to meet EN1434, as shown graphically below: